Upgrade Your Equipment Arsenal: Explore the Best Dirt Screen for Sale out there

Upgrade Your Equipment Arsenal: Explore the Best Dirt Screen for Sale out there

Blog Article

Enhance Material Recuperation With State-Of-The-Art Dirt Screens for Recycling Facilities

Just how precisely do dirt displays improve product recuperation? In this conversation, we will certainly explore the responses to these concerns and dig into real-life case studies that highlight the successful combination of dust screens in reusing centers. Prepare to discover the transformative power of advanced dirt displays and their effect on enhancing product recuperation.

The Significance of Dirt Screens in Recycling Facilities

Dust screens play an important role in reusing centers by effectively dividing dust and other impurities from recyclable materials. These displays, also referred to as trommel displays, are created to efficiently get rid of undesirable debris and make certain that usable and just tidy materials are refined additionally.

The primary feature of dust screens is to separate bigger items of dust, rocks, and various other non-recyclable products from the stream of products. By doing so, they prevent these pollutants from getting in the reusing procedure and possibly destructive equipment or jeopardizing the top quality of the end product.

Furthermore, dust displays assist to improve the overall efficiency of recycling operations. By removing dirt and various other impurities early while doing so, the screens minimize the quantity of manual work needed to sort and cleanse the products later. This not just saves time however additionally raises and decreases expenses productivity.

Additionally, making use of dirt screens adds to environmental sustainability. By making sure that unpolluted and only clean materials are refined, reusing facilities can create higher-quality recycled products. This, subsequently, encourages making use of recycled materials in numerous sectors, lowering the demand for virgin sources and decreasing the ecological effect of source removal and production processes.

Exactly How Dirt Screens Improve Material Recovery

Making use of dirt screens in recycling centers significantly enhances the process of product healing. These screens play an important role in dividing dust, debris, and other undesirable materials from the recyclable stream, resulting in enhanced performance and better result.

Among the primary methods which dust screens enhance material recovery is by getting rid of pollutants that can hinder the recycling process. Dust, rocks, and other non-recyclable products can create damage to tools, decrease the effectiveness of succeeding sorting processes, and infect the final recycled products. By successfully screening out these contaminants, dust screens aid make sure that the recyclable materials remain pure and of excellent quality.

Moreover, dust screens allow recycling centers to recover a higher amount of beneficial products. By removing dirt and particles, the screens enable an extra accurate sorting procedure, enhancing the healing rate of recyclable products. This implies that even more beneficial sources can be recovered and recycled, reducing the requirement for virgin products and lessening the environmental effect linked with their extraction and production.

In enhancement to enhancing product recovery, dirt displays also add to the total efficiency of recycling facilities. By preventing tools damages and decreasing downtime created by obstructions and clogs, these screens assist keep a nonstop and smooth recycling procedure. This enhanced performance converts right into price savings and enables greater throughput, ultimately improving the earnings and sustainability of reusing operations.

Secret Attributes of State-of-the-Art Dust Screens

To further enhance the effectiveness and efficiency of material healing in recycling centers, state-of-the-art dirt displays are equipped with vital attributes that optimize the splitting up procedure and make certain the highest possible top quality output (dirt screen for sale). These features consist of sophisticated screening modern technology, customizable setups, and durable building and construction

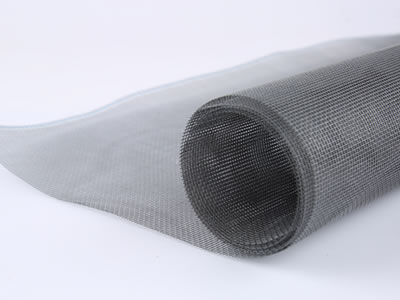

One trick attribute of state-of-the-art dust displays is their sophisticated screening innovation. These displays are designed with precision-engineered mesh or perforated plates that efficiently different dust and debris from the recyclable materials. The size and spacing of the openings in the screens can be customized to suit different sorts of products, enabling efficient separation and optimum recovery prices.

One more vital function of these dust displays is their personalized setups. Recycling centers can change the speed, angle, and amplitude of the displays to maximize the separation procedure. This versatility allows operators to tweak the displays according to the certain requirements of the products being processed, leading to boosted precision and higher recuperation rates.

In addition, advanced dust screens are constructed with durable building and construction to endure the harsh problems of reusing centers. They are made from resilient products such as stainless steel or high-strength alloys, making sure longevity and marginal downtime because of upkeep or repair work. In addition, important source these screens are made with very easy access for cleaning and upkeep, reducing and helping with effective operations downtime.

Actions to Implementing Dirt Screens in Recycling Facilities

What are the essential actions for integrating dirt screens into recycling centers? Implementing dust displays in recycling facilities involves a methodical method to guarantee effective installment and procedure. The following are the essential steps to efficiently include dirt screens:

Evaluation: Conduct an extensive analysis of the facility's needs and requirements to determine the suitable dirt screen specifications. Think about factors such as material type, volume, and wanted separation performance.

Setup: Prepare the facility for the setup of the dust displays. This may involve retrofitting existing tools or producing room for brand-new installations. Comply with maker standards and guarantee appropriate placement and integration with the reusing process.

Evaluating and Calibration: Once the dust displays are set up, carry out thorough screening to make certain proper functioning. dirt screen for sale. Adjust the system to attain wanted splitting up performance and minimize material loss

Training and Maintenance: Train personnel on operating and keeping the dirt screen system. Establish a routine maintenance routine, including cleaning and assessment, to make certain optimal performance and long life.

Study: Successful Material Healing With Dirt Screens

Integrating dust screens into reusing facilities has actually proven to be an effective method for achieving reliable material healing, as shown by several study. These study highlight the favorable impact of dust displays on the general recycling procedure.

By executing dust screens, the facility was able to substantially minimize the amount of contamination in their recyclable materials. The introduction of dirt screens likewise aided to tear and reduce the wear on sorting equipment, decreasing maintenance expenses and downtime.

Another study showcases a country recycling facility that had check over here problem with excessive dust and debris in their inbound waste stream. By mounting dust displays, the facility had the ability to get rid of a huge part of the unwanted products, leading to cleaner recyclables and enhanced effectiveness in the sorting process. This led to higher material recovery prices and minimized waste sent to the landfill.

These study demonstrate that incorporating dirt displays into reusing Web Site centers can have a substantial positive influence on product healing. By effectively removing dust, debris, and other impurities, reusing centers can boost their general recycling rates, lower garbage dump waste, and take full advantage of the worth of recovered products.

Final Thought

Finally, the usage of advanced dust screens in reusing centers is essential for boosting product recuperation. These displays properly remove dirt and debris, allowing for the reliable splitting up and recovery of beneficial products. By executing dust displays, recycling facilities can considerably boost their recycling procedures and add to a more lasting future.

One of the main means in which dust displays enhance product recovery is by getting rid of contaminants that can impede the reusing process. By successfully screening out these pollutants, dust screens help make certain that the recyclable materials stay pure and of high top quality.

Additionally, dust displays enable recycling centers to recoup a greater quantity of beneficial materials.In addition to enhancing product recuperation, dirt screens likewise add to the total efficiency of recycling centers.In final thought, the usage of advanced dust screens in reusing facilities is essential for improving product recovery.

Report this page